How to Choose the Best Polyester Staple for Your Needs?

Choosing the right polyester staple can be a daunting task. With many options available, it’s easy to feel overwhelmed. Polyester staple is used in various applications, from textiles to insulation materials. Understanding the key factors in your decision is crucial.

Consider the properties of polyester staple. Think about your specific needs. Some staples are thicker, while others are finer. The fiber length can influence the texture and durability of the final product. When selecting, always assess the application area and desired qualities.

Reflect on the sourcing as well. Not all polyester staple is of equal quality. Recycled options are growing in popularity, but they may not perform as well in some products. Balancing cost and performance is essential. It can be tricky to find the perfect fit. Understanding these elements can lead to a more informed decision.

Understanding Polyester Staple Fiber and Its Applications

Polyester staple fiber is a versatile material widely used in various applications. It is made from polyester, a synthetic polymer that is durable and resilient. The properties of polyester make it a popular choice for textiles and non-woven fabrics. For instance, it can be found in clothing, upholstery, and insulation products. Its ability to resist wrinkles and shrinking further enhances its appeal.

Understanding how polyester staple fibers work can aid in making the right choices for specific projects. For example, fibers can vary in length and thickness. Shorter fibers are often used in spinning yarn, while longer ones might be better for insulation. Different characteristics may affect the feel and performance of the final product. It's important to consider the end use before deciding on the type of polyester staple.

Despite its advantages, some drawbacks exist. Environmental concerns arise from polyester's reliance on fossil fuels. Additionally, the fibers may not provide the same level of breathability as natural fibers. It's essential to weigh these factors carefully. Exploring alternatives could lead to better solutions, depending on your needs and values. Understanding these dynamics is crucial for anyone considering polyester staple for their projects.

Factors to Consider When Selecting Polyester Staple

When selecting polyester staple, it's crucial to consider fiber length. Longer fibers often create smoother yarns. However, they may come with a higher price tag. On the flip side, shorter fibers can be more economical. But, they may lead to lower fabric strength. This is a delicate balance to strike, particularly for specific applications.

Another important factor is fiber denier. Denier measures fiber thickness. A higher denier means thicker fibers, leading to a more durable fabric. Yet, thicker fibers can feel harsher against the skin. Softness is key for garments but may impact durability. Many overlook this trade-off, but it can alter the final product significantly.

Density should also be evaluated. More densely packed fibers typically lead to stronger fabrics. These fabrics tend to be resilient, but their weight can be a concern for certain projects. Keep in mind the end-use of the fabric. An outdoor application may need heavier, dense materials, while a lightweight garment may require the opposite. Balancing these factors requires careful thought and sometimes, trial and error.

Comparing Different Types of Polyester Staple Fibers

Choosing the right polyester staple fiber can be challenging. Various types exist, each suited for different applications. For example, hollow fibers are excellent for insulation and warmth, while solid fibers offer durability. According to industry reports, hollow polyester fiber provides up to 20% more thermal efficiency than solid types.

When evaluating polyester staple fibers, consider the denier weight. Lower denier fibers are generally softer and more lightweight. In contrast, higher denier fibers are sturdy and provide bulk. Both have their advantages, but the choice depends on your end application. The industry averages suggest that a denier range of 3 to 15 is versatile for numerous functions.

Tip: Always test small samples before making large orders. This helps ensure the fiber meets your desired properties. Pay attention to the fiber’s resilience against wear and tear. Check for any potential issues in production processes. Lastly, consider environmental certifications for sustainability.

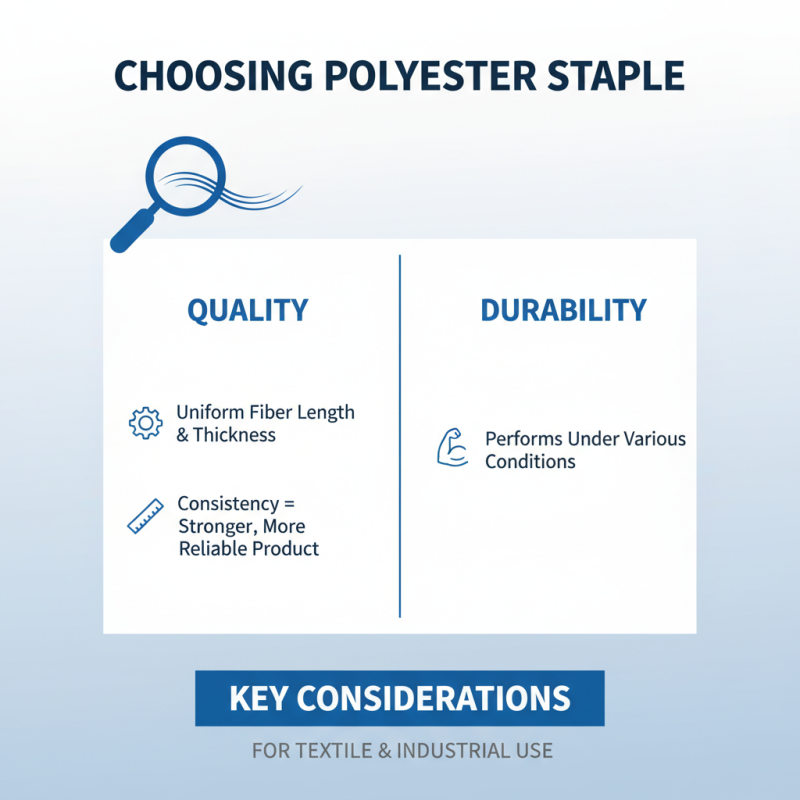

Evaluating Quality and Durability of Polyester Staple

Choosing the right polyester staple involves careful consideration of quality and durability. Quality is key; it defines the fiber's overall performance. Look for uniformity in fiber length and thickness. Consistency ensures that the final product will be stronger and more reliable. Durability matters too, as it impacts how the staple performs in various conditions.

Tips: Test the fiber by feeling its texture. A sturdy, resilient feel often indicates good quality. Also, pay attention to the tensile strength. Strong fibers resist breaking easily.

Beyond appearance, consider the environmental impact of the polyester staple. Not all fibers are created equal. Some may wear down faster, creating waste. Think about your long-term needs. Would you benefit from a staple that withstands heavy use?

By focusing on these points, you can make a well-informed choice. This ensures that the selected polyester staple meets your specific needs.

Tips for Sourcing and Purchasing Polyester Staple Fiber

When sourcing polyester staple fiber, many factors must be considered. First, understand the fiber's quality and specifications. According to industry reports, the market for polyester staple fiber is projected to grow steadily, driven by increasing demand across textiles and nonwovens. A critical measure of quality is fiber denier, which affects the final product's softness and durability.

**Tips for Sourcing: Look for suppliers who offer detailed product specifications. Quality certifications are also important. They ensure the fiber meets industry standards. Pay attention to the source of raw materials. Recycled options are becoming more popular, offering an eco-friendly alternative.**

Evaluate potential suppliers based on their reputation. Reading reviews and case studies can provide insights. Don't rush into decisions; consider samples before making larger purchases. The right choice can enhance your product quality but mistakes might lead to higher costs and customer dissatisfaction. Research shows that nearly 20% of businesses face quality issues due to improper sourcing. Make informed choices.

Related Posts

-

2025 Top Trends in Polyester Staple: Innovations and Applications

-

Exploring the Versatility and Sustainability of Polyester Staple in Modern Textiles

-

Understanding Polyester Staple: The Key Ingredient in a $540 Billion Global Textile Industry

-

Top 10 Tips for Choosing the Best Polyester Staple for Your Projects

-

2025 Top 10 Washing Reusable Sanitary Padsfiber for Eco Friendly Menstrual Care

-

Understanding the Production Standards for the Best Everyday Sanitary Pads Fiber in the Global Market