Top 10 Tips for Choosing the Best Polyester Staple for Your Projects

Choosing the right polyester staple for your projects can significantly impact the quality and performance of your final product. Polyester staples are versatile fiber options widely used in various applications, from textiles to composites. With numerous types of polyester staples available in the market, it can be challenging to identify the best choice for your specific needs. Understanding the characteristics and benefits of polyester staple fibers is essential for making an informed decision.

In this guide, we will explore the top 10 tips for selecting the perfect polyester staple for your projects. Whether you are working on apparel, upholstery, or industrial applications, these insights will help you navigate the complexities of choosing the right polyester staple. By considering factors such as fiber properties, performance requirements, and environmental impact, you can ensure that your selection aligns with your project goals effectively.

Understanding Polyester Staple: Key Properties to Consider

When choosing the right polyester staple for your projects, understanding its key properties is crucial.

Polyester staple fibers are renowned for their durability, resistance to wrinkling, and ability to retain color, making them a preferred choice in various applications,

from textiles to non-wovens. According to the Fiber Economics Bureau's 2021 report,

polyester continues to capture over 50% of the global fiber market due to its versatility and affordability.

These characteristics enable it to outperform natural fibers in performance-related aspects, thus making it a popular option for manufacturers seeking

cost-effective solutions without compromising on quality.

Another essential factor to consider is the denier of the polyester staple, which refers to the thickness of the fiber.

Thinner fibers (low denier) can produce softer, more drapable fabrics suitable for apparel, while thicker fibers (high denier)

are better suited for applications requiring greater strength, like upholstery and industrial products.

Research from the Textile World Magazine indicated that using blends of different denier fibers can enhance

fabric properties, such as softness and strength, providing an optimal balance for specific project requirements.

Ultimately, knowing the appropriate denier and understanding the inherent properties of polyester staple

will ensure you choose the best option to meet the needs of your project effectively.

Evaluating the Fiber Length and Fineness for Project Suitability

When selecting the best polyester staple for your projects, evaluating fiber length and fineness is crucial to achieving the desired fabric characteristics. Fiber length significantly influences the texture, strength, and overall quality of the end product. According to a report by the Textile Research Institute, longer fibers tend to create smoother and stronger yarns, which can enhance the durability of finished textiles. For applications that require high tenacity, such as workwear or upholstery, it is advisable to opt for polyester staples with longer fibers, typically in the range of 32 mm to 64 mm.

Fineness, on the other hand, affects the softness and drape of the fabric. The finer the fiber, the softer the handle and more fluid the drape of the fabric. Industry standards indicate that fibers with a denier of 1.5 to 3.0 can be ideal for clothing applications since they balance lightness with structural integrity. When considering fiber fineness, it's important to match the denier to the application; finer staples may be suitable for lightweight fabrics, while heavier deniers are best for robust uses.

Tip: Before finalizing your selection, always request samples of different fiber lengths and fineness to evaluate how they perform in your specific project applications. This hands-on assessment can provide invaluable insight into how the choice of polyester staple influences the overall quality of your finished products, ensuring that your results meet or exceed expectations.

Top 10 Tips for Choosing the Best Polyester Staple for Your Projects - Evaluating the Fiber Length and Fineness for Project Suitability

| Tip Number | Evaluation Criteria | Fiber Length (mm) | Fineness (Dtex) | Project Suitability |

|---|---|---|---|---|

| 1 | Choose Appropriate Fiber Length | 32 | 1.1 | Ideal for knitted fabrics |

| 2 | Consider Fineness for Softness | 38 | 1.4 | Great for soft-touch applications |

| 3 | Evaluate Tenacity | 48 | 2.0 | Suitable for high-stress applications |

| 4 | Assess Resilience | 40 | 1.8 | Recommended for upholstery |

| 5 | Check for UV Resistance | 30 | 1.0 | Ideal for outdoor fabrics |

| 6 | Analyze Moisture Wicking | 36 | 1.5 | Suitable for activewear |

| 7 | Prioritize Colorfastness | 34 | 1.2 | Recommended for fashion textiles |

| 8 | Select Based on Application | 50 | 2.1 | Versatile for various products |

| 9 | Review Blending Options | 42 | 1.3 | Improves overall quality |

| 10 | Consider Eco-Friendliness | 38 | 1.4 | Ideal for sustainable products |

Comparing Different Types of Polyester Staple for Performance

When selecting the best polyester staple for your projects, it's essential to compare the various types available and their performance characteristics. One of the primary factors to consider is the denier, which measures the fiber thickness. Lower denier fibers tend to be finer and softer, making them ideal for applications requiring a soft handfeel, such as bedding or apparel. In contrast, higher denier fibers are more durable and are often used in applications that demand strength, like carpets or outdoor fabrics.

Another critical aspect to consider is the loft of the polyester staple. Loft refers to the fiber's ability to hold air and maintain bulk. Higher loft fibers provide excellent insulation and are often used in products like pillows and jackets. However, lower loft fibers may offer better compression characteristics, making them suitable for products where space-saving storage is vital.

When choosing the right polyester staple, consider the end use and performance requirements of your project. Ensure you evaluate any specific needs such as moisture-wicking properties or resistance to wear and tear. By understanding these differences, you’ll be better equipped to select the polyester staple that will ensure the success of your project.

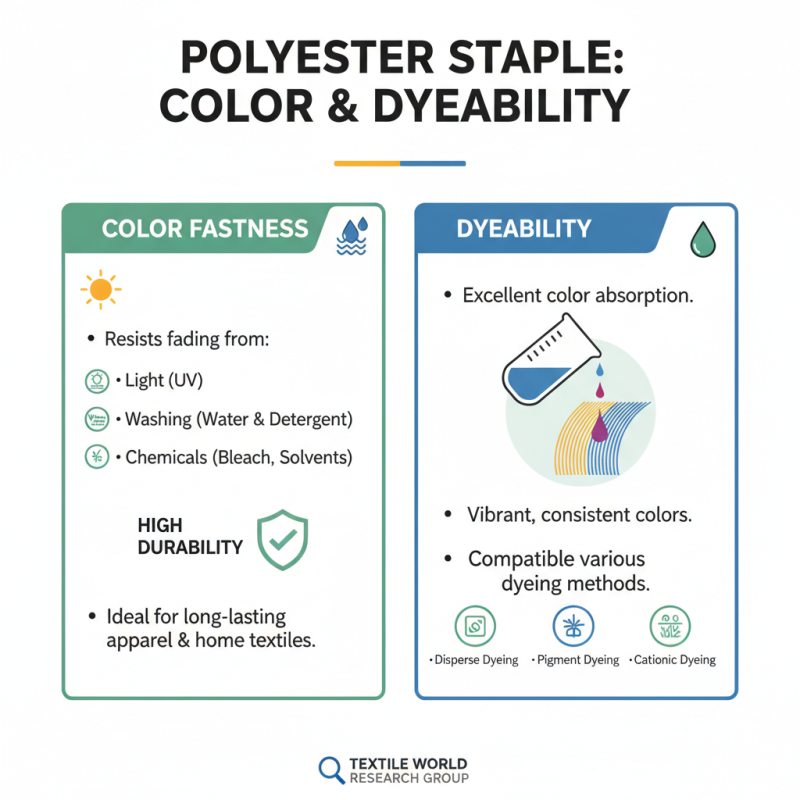

Assessing Color Fastness and Dyeability in Polyester Staple

When selecting polyester staple for various projects, assessing color fastness and dyeability is crucial. Color fastness refers to a material's ability to retain its original hue when subjected to environmental conditions such as light, washing, and exposure to chemicals. According to a report by the Textile World Research Group, polyester fibers typically exhibit high color fastness, making them a popular choice in manufacturing. This durability is particularly beneficial for end products that demand longevity and consistent aesthetic appeal, such as apparel and home textiles.

Dyeability, on the other hand, indicates how well a fiber can absorb dyes. Polyesters can be notoriously challenging to dye due to their hydrophobic nature. However, advancements in dyeing techniques have improved the dyeability of polyester staples significantly. The Global Textile Dyeing Market Report indicates a growing demand for solution-dyed polyester, which involves incorporating color into the fiber before it is spun, ensuring vibrant and long-lasting colors. This process not only enhances color fastness but also minimizes the environmental impact of water-intensive dyeing, positioning it as a sustainable choice for manufacturers aiming to meet eco-friendly standards. By understanding these characteristics, you can make informed choices that elevate the quality and marketability of your projects.

Choosing Sustainable Options: Eco-friendly Polyester Staple Availability

When selecting polyester staple for your projects, it is increasingly important to consider sustainability. Eco-friendly polyester staples are crafted from recycled materials, which helps reduce waste and the environmental impact associated with virgin polyester production. By choosing sustainable options, you not only support eco-conscious manufacturing practices but also contribute to a circular economy where materials are reused and repurposed effectively.

Furthermore, the growing availability of sustainable polyester staples provides a viable alternative for designers and manufacturers who wish to prioritize eco-friendliness in their work. Many suppliers now offer products that meet stringent environmental standards, ensuring that your projects can achieve both aesthetic appeal and responsible sourcing. Investigating certifications and production methods can help guide your choice, allowing you to confidently incorporate these sustainable materials into your creations while promoting a greener future in the textile industry.

Related Posts

-

Understanding Polyester Staple: The Key Ingredient in a $540 Billion Global Textile Industry

-

Exploring the Versatility and Sustainability of Polyester Staple in Modern Textiles

-

2025 Top Trends in Polyester Staple: Innovations and Applications

-

How to Choose the Right Polyester Staple for Your Textile Production Needs

-

Your Ultimate Guide to Everyday Sanitary Pads Fiber: Understanding Health Benefits and Eco-Friendly Choices

-

The Future of Hydrophobic Natural Fibers in Sustainable Textile Innovation