How to Use Fiber Polypropylene in Your Projects?

Fiber Polypropylene has become an essential material in various industries due to its versatility and strength. Dr. Emily Parker, a leading expert in composite materials, once stated, "Fiber Polypropylene enhances durability while reducing weight." This highlights its significant advantages in construction and manufacturing.

Incorporating Fiber Polypropylene into your projects requires proper understanding and application techniques. For instance, it can be used in textiles, automotive parts, and construction materials. The lightweight nature helps reduce overall project costs. However, one must be careful about the environmental impact. Fiber Polypropylene is not biodegradable and may contribute to waste if not handled responsibly.

Additionally, working with Fiber Polypropylene can present challenges. Understanding the right mixtures and processing methods can take time. Mistakes in application can lead to performance issues. Learning from these experiences is vital for success in your projects. As the industry evolves, continual improvement and adaptation are essential for utilizing Fiber Polypropylene effectively.

Understanding Fiber Polypropylene: Properties and Benefits

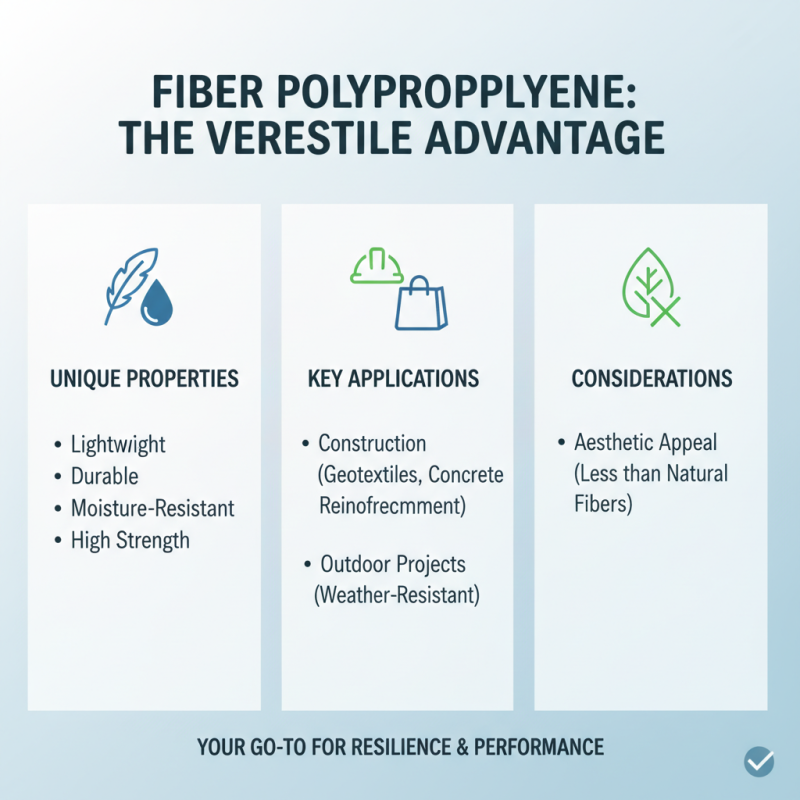

Fiber polypropylene is gaining attention in various projects due to its unique properties. This synthetic fiber is lightweight, durable, and resistant to moisture. Its strength makes it suitable for many applications, from construction to consumer goods. In fact, many find it a go-to material for outdoor projects, as it withstands environmental stress. Still, it sometimes lacks the aesthetic appeal of natural fibers.

One key benefit of fiber polypropylene is its cost-effectiveness. It is often cheaper than alternatives like cotton or wool. This makes it accessible for budget-conscious projects. However, some users notice it doesn’t have the same softness as traditional fabrics. This can be a drawback for clothing or upholstery applications. It's worth considering how this characteristic might impact user experience.

The versatility of fiber polypropylene is impressive. It can be woven into various forms, from geotextiles to carpets. It’s also recyclable, which appeals to environmentally conscious consumers. Nonetheless, the recycling process isn't always straightforward. Awareness of local recycling facilities is necessary for effective disposal. This consideration may lead to questions about responsibility in choosing materials.

Common Applications of Fiber Polypropylene in Various Industries

Fiber polypropylene is a versatile material that finds applications in various industries. It's lightweight, durable, and resistant to chemicals. These properties make it suitable for construction, automotive, and textile sectors.

In construction, fiber polypropylene is often used for reinforcing concrete. It improves crack resistance and overall durability. In automotive applications, it is utilized in insulation materials and underbody coatings.

In textiles, fiber polypropylene's moisture-wicking properties are beneficial. It dramatically improves comfort in clothing. You’ll see it used in activewear, outdoor gear, and even carpets. These uses showcase its adaptability across different fields.

Tips: When incorporating fiber polypropylene into your project, consider its thermal and mechanical properties. Understanding these can help you optimize your design. Test samples when possible. This will reveal how it interacts with other materials. Additionally, stay updated with technological advancements. This will ensure you are using the best methods available.

Preparing Your Project: Tools and Materials Needed

When preparing to use fiber polypropylene in your projects, the right tools and materials are essential. Start with basic tools like scissors or a utility knife. You'll need a ruler for precise measurements and a cutting mat to protect surfaces. A heat source, such as a heat gun, can help seal edges effectively. Safety gear is also important. Gloves and goggles can protect you from sharp edges and potential burns.

Gathering your materials is the next step. Fiber polypropylene comes in various thicknesses and colors. Choose the one that fits your project needs. For bonding, you may require adhesives specifically designed for polypropylene. These can be tricky; some may not adhere well. Experimenting with different types might lead to better results.

Don't forget about proper workspace organization. A cluttered area can lead to mistakes. You'll likely encounter challenges, like uneven cuts or insufficient bonding. Documenting these mistakes can help in refining your technique. Each project is a learning opportunity, reminding you that perfection isn’t always the goal. Embrace the process, and your skills will develop over time.

Step-by-Step Guide to Incorporating Fiber Polypropylene

Fiber polypropylene is a versatile material that can enhance various projects. Its lightweight nature makes it easy to handle. When incorporating fiber polypropylene, start by gathering the right tools. You will need scissors, a cutting mat, and adhesive suitable for plastics. Measure the required length of the fiber polypropylene carefully. Precision is key in achieving a clean cut.

After cutting, consider the application method. This material can be used for reinforcement or as a standalone element. When attaching to surfaces, ensure they are clean and dry. Apply the adhesive evenly. Watch for air bubbles; they can compromise the bond. Sometimes, it’s challenging to achieve a perfect adhesion. Don't hesitate to reapply adhesive if needed. Testing a small section before the main application can help.

As you work, reflect on any difficulties you encounter. Are you managing the material effectively? Perhaps using different adhesives could yield better results. Document your process, so you can improve over time. Fiber polypropylene can be tricky, but it offers great potential when used skillfully.

How to Use Fiber Polypropylene in Your Projects? - Step-by-Step Guide to Incorporating Fiber Polypropylene

| Step | Action | Materials Needed | Tips |

|---|---|---|---|

| 1 | Select Fiber Polypropylene | Fiber Polypropylene Rolls | Choose a thickness based on your project needs. |

| 2 | Measure and Cut | Measuring Tape, Scissors | Ensure accurate measurements to reduce waste. |

| 3 | Prepare the Surface | Cleaner or Degreaser | Ensure the surface is clean for better adhesion. |

| 4 | Apply Adhesive | Adhesive Suitable for Polypropylene | Follow manufacturer instructions for best results. |

| 5 | Place Fiber Polypropylene | Weight or Roller | Apply even pressure to ensure full contact. |

| 6 | Finishing Touches | Scissors, Edge Sealer | Seal edges to prevent fraying. |

Best Practices for Maintenance and Durability in Fiber Projects

Fiber polypropylene (PP) has gained popularity in various industries due to its lightweight nature and durability. When using PP fiber in projects, maintenance plays a crucial role in ensuring long-lasting results. According to industry reports, properly maintained fiber composites can extend life expectancy by up to 50%. Regular inspections help detect wear and tear early.

Cleaning fibers is essential. Avoid harsh chemicals, as they can degrade the material. Simple soap and water usually suffice. Ensure thorough rinsing as leftover soap can attract dirt. Interestingly, many projects overlook this simple yet effective step, leading to reduced durability over time.

Another aspect to consider is UV exposure. Prolonged sunlight can weaken polypropylene fibers. Utilizing UV stabilizers in your projects can help mitigate this issue. Studies show that fibers treated with UV stabilizers remain strong longer. However, not all projects take this into account, risking premature failure. Balancing cost with durability is a challenge that requires careful consideration.

Related Posts

-

Ultimate Guide to Choosing the Right Fiber Polypropylene Products for Your Business Needs

-

5 Smart Tips to Choose the Right Fiber Polypropylene for Your Needs

-

What is Fiber Polypropylene and How is it Used?

-

Top 10 Tips for Choosing the Best Polyester Staple for Your Projects

-

How to Choose the Best Sustainable Sanitary Pads for Your Period Health in 2023 with Proven Eco-Friendly Benefits

-

What Are Sanitary Towels For Swimming and How To Use Them Safely